Experience and expertise

Our desire to improve and upgrade according to the needs of our customers leads to the gradual refreshing of individual technologies.

- 2017 - our beginning as a powder paint shop for large steel parts.

- 2018 - added aluminum pretreatment. This installation makes us one of the largest paint shops in Europe with a unique option to implement powder coating in projects where wet paint would have been the only option due to the size of aluminum parts.

- 2019 - building a special bonding room with controlled humidity, temperature, and light. For demanding customers we apply sealant before and after application, in special projects between each paint layer.

- 2020 - with the growing volume of our projects supplied in JIT mode we expanded our roofed storage and handling spaces with a 50 x 30 m area.

- 2021 - the last installed technology is the sanding box with a closed circuit and recycling. This technology allows sanding parts up to the size of 10*2,5*1,5 meters.s

Tools for quality improvement and processes are set according to the Qualicoat standards. The quality and expertise are regularly checked through ISO audits, but also through regular audits by our customers. Since the beginning of our work on global train projects, our operations have been audited by Alstom, Knorr-Bremse MERAK, Knorr-Bremse IFE, Faiveley. Apart from these important audits, our projects have been approved during strict “First article inspections” by our customers Siemens, Stadler, Thermo King, Bombardier. A significant proportion of our work can be seen in construction projects where the visual aspect and quality are ensured. We contributed to projects AFI City Prague, Komplex Rustonka Prague, LA Galaxi, which you can view in the section “Application”.

Experienced personnel with longtime expertise in the area of coating and surface treatment is the basis of our successful development. Do you still coat particles in wet pain even though powder coating offers significant savings? Is somebody telling you that powder paint has inadequacies compared to wet paint? We would be glad to discuss this with you and find a possible solution.

Write to us!Our paint shop’s application

LOOK THROUGH OUR RESULTSEstablishment

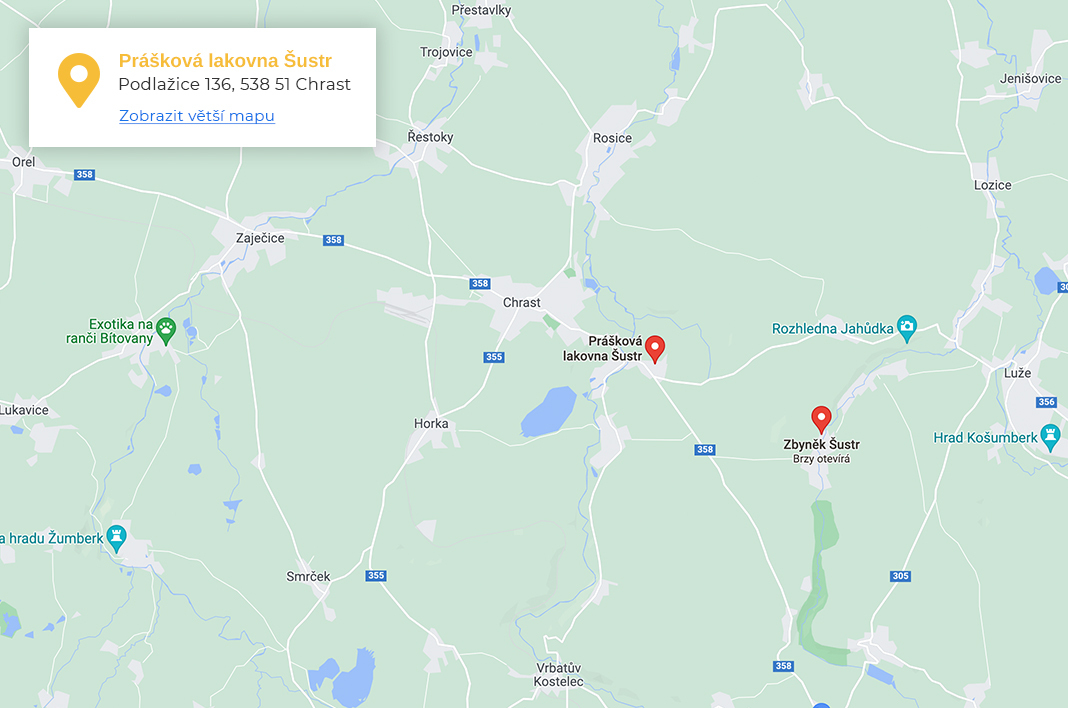

- Podlažice 136, 538 51, Okres Chrudim

Billing address:

- Zbyněk Šustr s.r.o. | Hroubovice 69 538 54 Hroubovice

- IN 28784278 | TIN CZ28784278

Demands

- info@sustrgroup.com | +420 777 308 776 (and international trade)